SERIES WELDING

Our series welding is a fully automatic process that is completed using a total of five sensor-guided robotic welding systems. These enable us to machine components with a maximum length of eleven metres and a weight of up to ten tonnes per unit, in alternating operations.

In addition to this, our gantry welding system also allows us to machine products in tandem – for shorter production times and even better results.

Our three-shift operation model guarantees maximum efficiency, punctuality and consistently high quality in our production.

Facts

- 5 robotic welding systems

- Maximum component length: 11 metres

- Weight: Up to 10 tonnes per unit

- Three-shift production model

- MAG welding with 0.8 - 1.6 mm filler wire t

- Tandem welding process (2 wire welding processes for high-speed welding)

- PTA plasma transfer arc welding (perfect for coatings and hard coating)

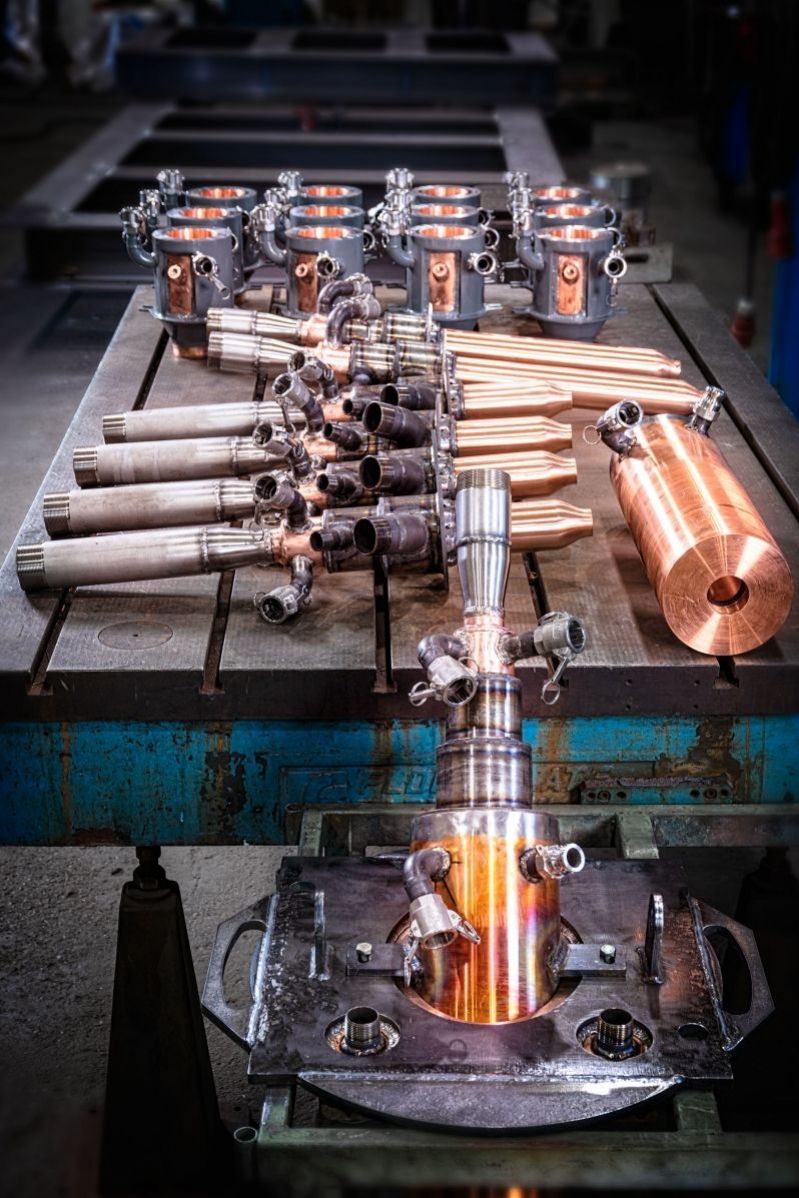

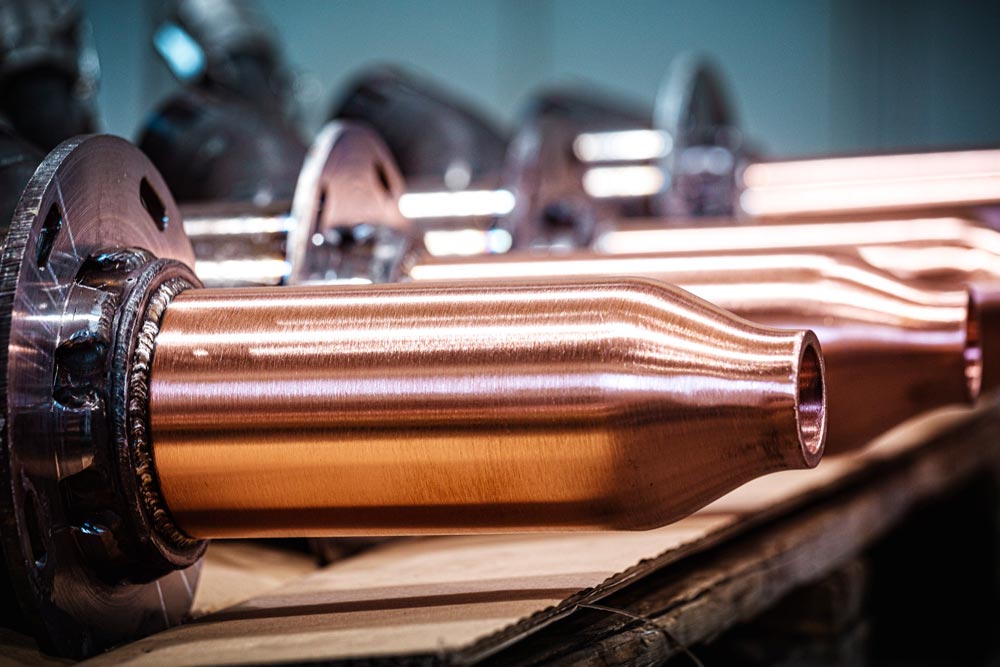

COPPERWORKING

Copperworking (copper welding) is one of our core areas of expertise. From new constructions to restorations, we offer a comprehensive service for steelworks all around the world. And for us, optimisations that aim to improve processes for existing components are all part of the job.

Our comprehensive service include component collection, restoration and transport back to the customer. New components are discussed with the customer on an individual basis and tailored to suit their particular processes. stahlotec has years of experience in this field and has developed its own products for optimising the melting process.

The portfolio of products we provide for the steelworking industry ranges from copper cooling elements for electric arc and blast furnaces, custom firing systems, electrically conductive components, contact plates and carrying arms to process optimisation for electric furnaces.

On request, dimensioning and the design consultation can be carried out at the customer’s site – anywhere in the world. The same applies to the maintenance, servicing and collection of the systems in question.

Facts

- Construction of hydronic and electrically conductive components

- All production performed in-house

- Full service for steelworks worldwide (defective components collected for restoration)

- Weight: Up to 10 tonnes per unit

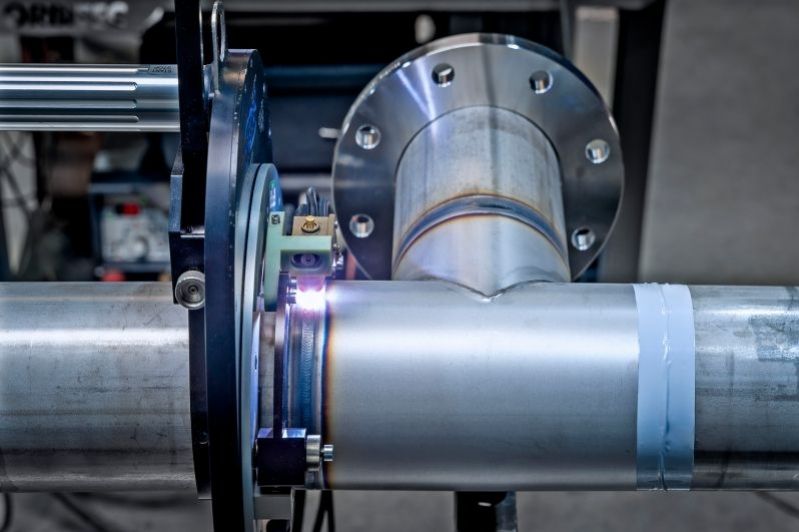

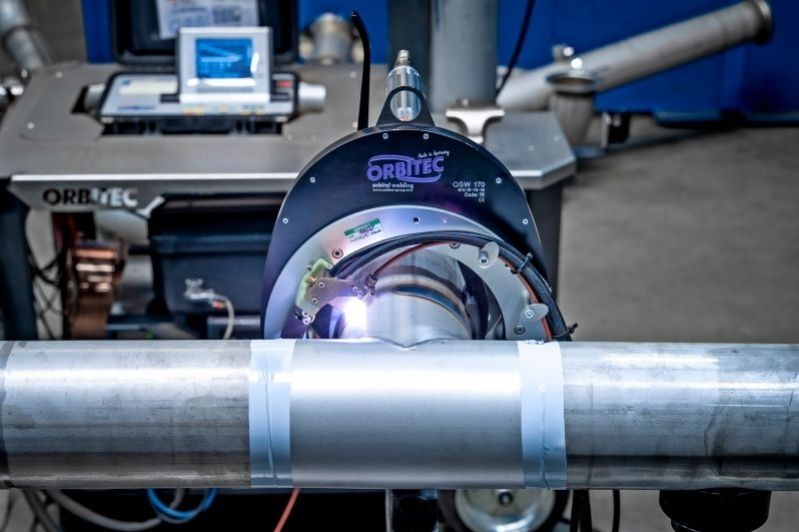

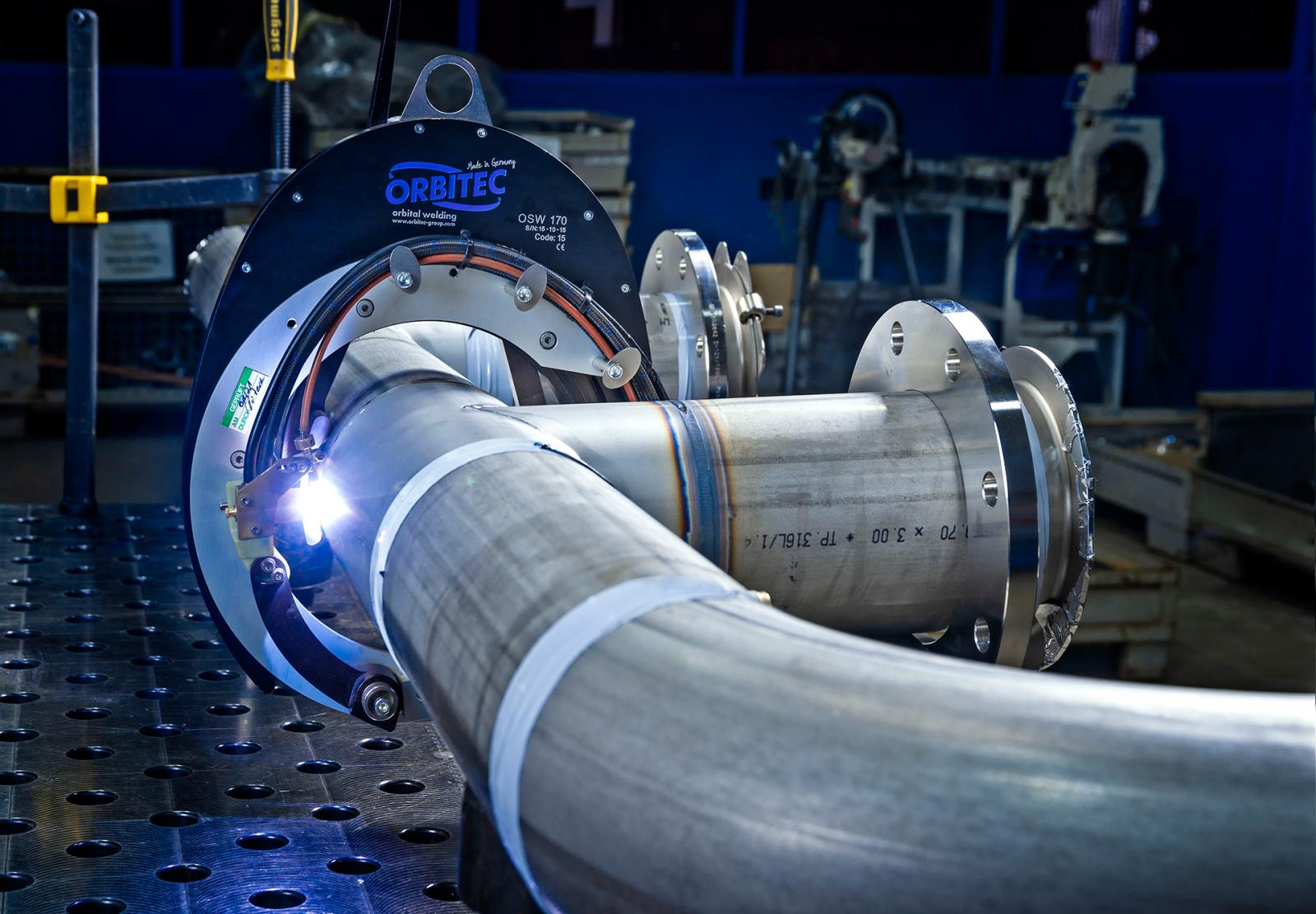

PIPELINE AND PIPING SYSTEM CONSTRUCTION

Thanks to our compliance with the AD 2000 Code on Pressure Vessels and the qualifications of our specialist personnel in this field, we are certified for the production of pressure vessels, pipelines, and measurement and control sections. We make pipelines from steel, stainless steel, copper and compounds using orbital and manual welding processes that are both reliable and reproducible. With a whole host of certified welding engineers, welding specialists, welding instructors and master welders on our books, we can inspect components to ensure that they fulfil the required quality standards before they even leave our factory.

For measurement and control sections, we offer unrestricted traceability, test certificates and documentation of the orbital welding procedure, including details of all the filler metals used, the welding time and the process instructions.

Facts

- Production of pressure vessels and pipelines

- Measurement and control sections

- AD2000-certified

- Certified to Germanischer Lloyd standards

- Steel, stainless steel, copper and aluminium pipelines

- Production using the orbital welding process

WEAR PROTECTION

Efficient use of resources, increasing the service life of components, avoiding downtime and optimising capacity utilisation are all key issues in the modern industrial setting. This is why our wear protection services use the latest production processes to make components, spare parts and wear parts that meet the most demanding of standards in terms of wear and corrosion protection.

Our range of services includes mobile spectral analysis, LMD laser cladding and fusion welding, laser hardening, PTA plasma transfer arc welding, and MIG/MAG welding with single and dual filler wire, up to weights of ten tonnes per unit and component lengths of up to eleven metres.

All our processes can be carried out manually, semi-automatically or fully automatically. We also provide repairs and refurbishment for spare and wear parts (RetroFIT) and supply wear protection plates and products.

Thanks to the latest 3D measuring technology, we can identify and measure wear zones and components and carry out fully automated welding line calculations. Our trained team of experts uses stahlotec’s own wear analysis tools to identify the most common types of wear at the customer’s site and recommend appropriate wear protection measures.

Customers in the agricultural industry, roadworking, mining, and the steel, iron, glass, cement, refractory, brickwork and smelting industries have been placing their trust in the expertise of our wear protection specialists for years.

Facts

- Mobile spectral analysis

- LMD welding

- Laser hardening

- PTA plasma transfer arc welding

- MIG/MAG

- Single and dual filler wires

STEELWORKING AND METALWORKING

Traditional steel and metalworking is still an important part of our day-to-day work. We possess the highest execution class (EXC 4) in accordance with the DIN EN 1090 standard, and are thus approved to carry out the most demanding welding and repair tasks in the field of civil engineering.

We weld by hand using both MIG/MAG and WIG welding processes in situations where a fully automated process is not feasible due to factors such as component size. In addition to steel and stainless steel, which are the most commonly requested materials, we can also weld aluminium and copper. Thanks to the professional expertise of our employees, we are certified for welding on railway vehicles in accordance with CL1 DIN EN 15085-2 and for manufacturing Class Q1 and Q2 military products in accordance with DIN 2303.

"Our in-house jig construction facility guarantees a consistent level of quality in the products we manufacture – even for those produced in large quantities.

"

Facts

- Certified to EXC 4 DIN EN 1090

- Certified to CL1 DIN EN 15085-2

- Certified to DIN 2303 Q1 + Q2 (military products)

- Material types: Steel, stainless steel, aluminium and copper

- Specialist personnel: 2 welding engineers, 6 welding specialist

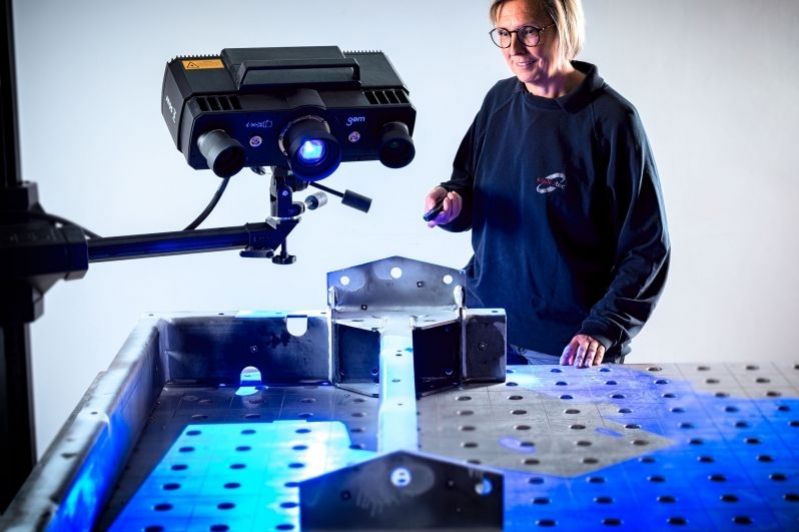

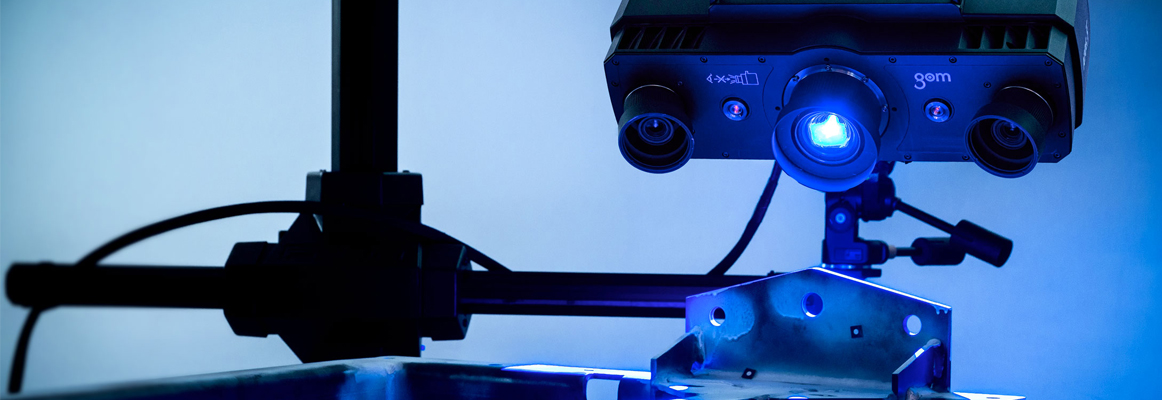

3D MEASUREMENT

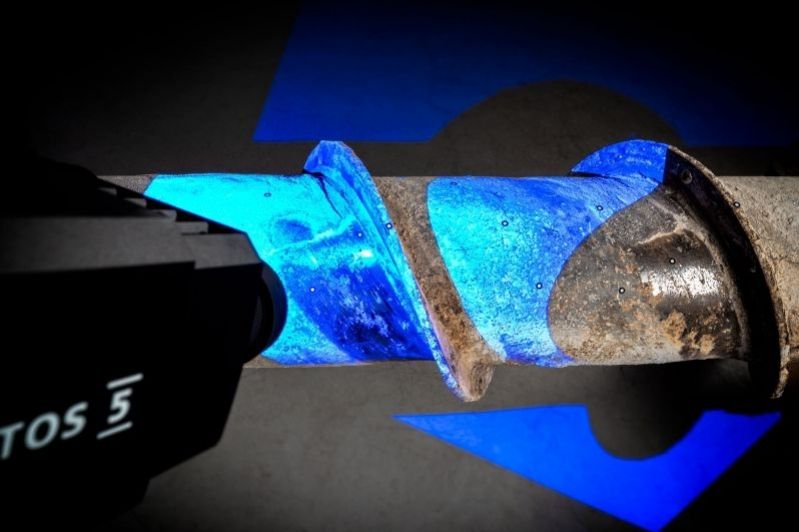

Thanks to the latest 3D measuring technology, we can verify the dimensional tolerances of components and equipment extremely quickly. The 3D scanner supplies precise, three-dimensional measurement data that allows us to optimise design and production processes. In addition to this, the high-speed measurement also helps to reduce production times and downtime, thus cutting costs significantly.

This new technology eliminates the need to spend valuable time generating 3D models separately. Instead, it measures our customers’ components and equipment at high speed and displays the 3D model once the process is complete. By comparing a worn component with its original CAD model, we can see how much it has changed since production and calculate its wear zones. In addition to providing us with documentation and measurement reports, the optical 3D measurement process also gives us directly readable data in various forms – such as a false-colour image that highlights the differences compared to the CAD or STEP model. This allows us to restore the worn areas automatically during the subsequent welding process. Another special feature of this technology is its ability to display and measure radii and free-form areas on complex components.

Facts

- Suitable for mobile use

- No limit in terms of component size

- Comparison between target and actual states

STAIRWAYS AND WORK PLATFORMS/RAILING AND BALCONY SYSTEMS/SAFETY EQUIPMENT

We produce stairways, work platforms, and railing and balcony systems for industrial and private use, and have many years of experience when it comes to making custom solutions.

We will handle every part of the process, from the consultation to the design, the production and the installation itself. We manufacture railing and balcony systems in a wide range of designs and materials (stainless steel, galvanised steel, coated steel), all tailored to suit your specifications and wishes. For use in public spaces, we offer special handrails with the antimicrobial material Cu+. In addition to the products listed above, we also make safety components such as ram protection equipment and bollards.

Facts

- Custom solutions

- Applications: Industrial, public sector, private use

- Safety equipment

- Everything from a single source

CONSTRUCTION

We develop solutions.

Our in-house Design department enables us to implement our customers’ wishes on an individual basis. Our employees design custom products to suit the customer’s specific application, all within the walls of our company.

Facts

- 3D space scanner measuring technology

- 3D design with a direct line to our Production time

LASER WELDING

Alongside conventional welding, we also use the innovative laser welding process. This enables us to produce high-precision workpieces with almost zero deformation, and is the perfect way to join materials with both high melting points and high thermal conductivity.

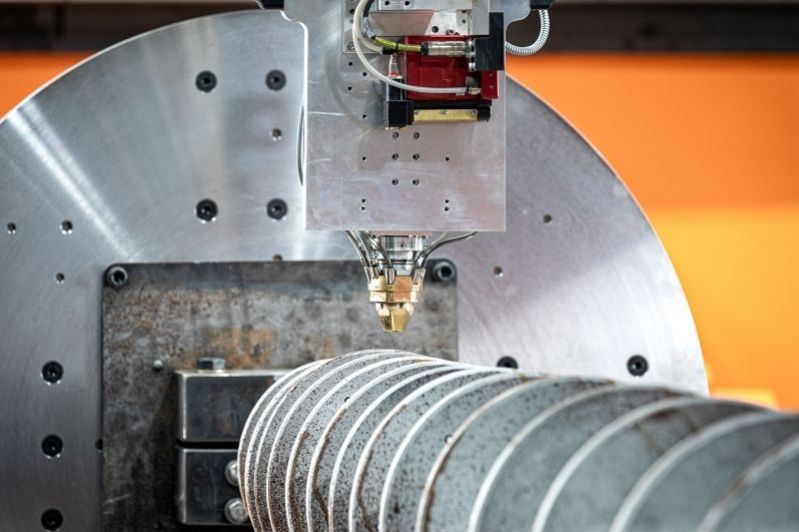

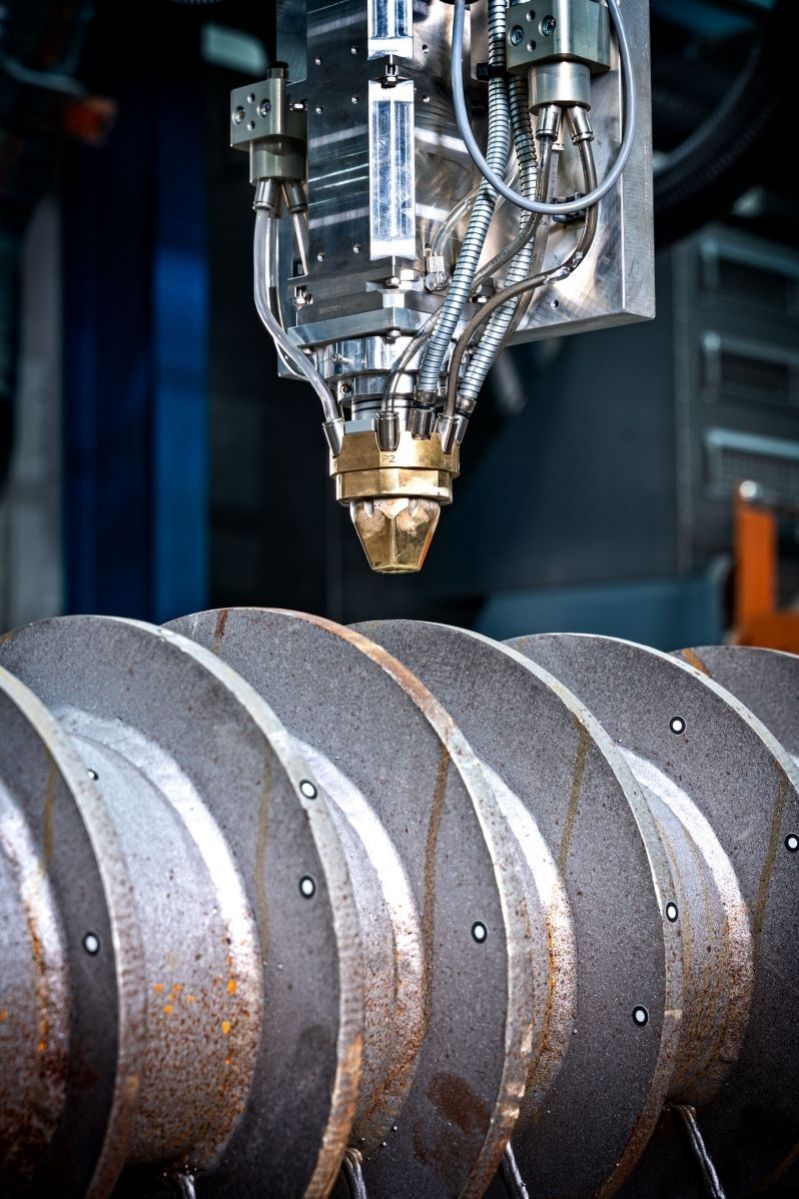

LMD – LASER CLADDING

Additive production with LMD (laser metal deposition) can be used to create special functional coatings with specific properties and alloys. For example, it can be used to print on components, precisely weld worn components in place, or apply wear protection coatings. Due to the low amount of heat used during this process, the required functions can be achieved with just a few layers of coating. This provides a number of advantages, including lower coating thicknesses, more efficient use of resources, and more lightweight components.

HEAT CONDUCTION WELDING/LASER DEEP PENETRATION WELDING

Our production plant can reliably handle processes for both heat conduction welding of thin metal sheets up to thicknesses of three millimetres and laser deep penetration welding for thicknesses of up to twelve millimetres. Thanks to the low amount of heat used in these processes and the fact that they do not require filler metal, they can be used to produce incredibly fine and precise welding seam geometries with very little thermal deformation and deep penetration.

LASER HARDENING

During the laser hardening process, the metal is heated up by the laser and then cooled down again. This process can be used to harden any type of steel that would otherwise be hardened using conventional means, and enables us to produce intelligent and partially hardened components. A pyrometer is used during the procedure to ensure that exactly the right amount of heat is used for the hardening process. This is controlled and logged completely automatically.

Facts

- Laser power: 10 kW

- Component length: Up to 10 metres

- Weight: Up to 5 tonnes per unit

- Heat conduction welding/deep penetration welding up to 12 millimetres

- Laser cladding

- Laser hardening

Copyright ©2025 stahlotec GmbH