ABOUT US

Since it was first founded 20 years ago, stahlotec has grown from a two-man company to become a certified and respected welding company that specialises in metal joining technology. Our core area of expertise is the machining and processing of steel, stainless steel, aluminium and copper.

Now a medium-sized business with more than 80 employees, we make products for a wide range of industries at our headquarters in Hagen a.T.W., northwest Germany.

WHO WE ARE

We value the importance of treating our customers and suppliers as equal partners. They provide the foundation that allows us to build lasting business relationships

that can withstand whatever challenges the market throws at us and provide a secure future for our company.

SEE FOR YOURSELF

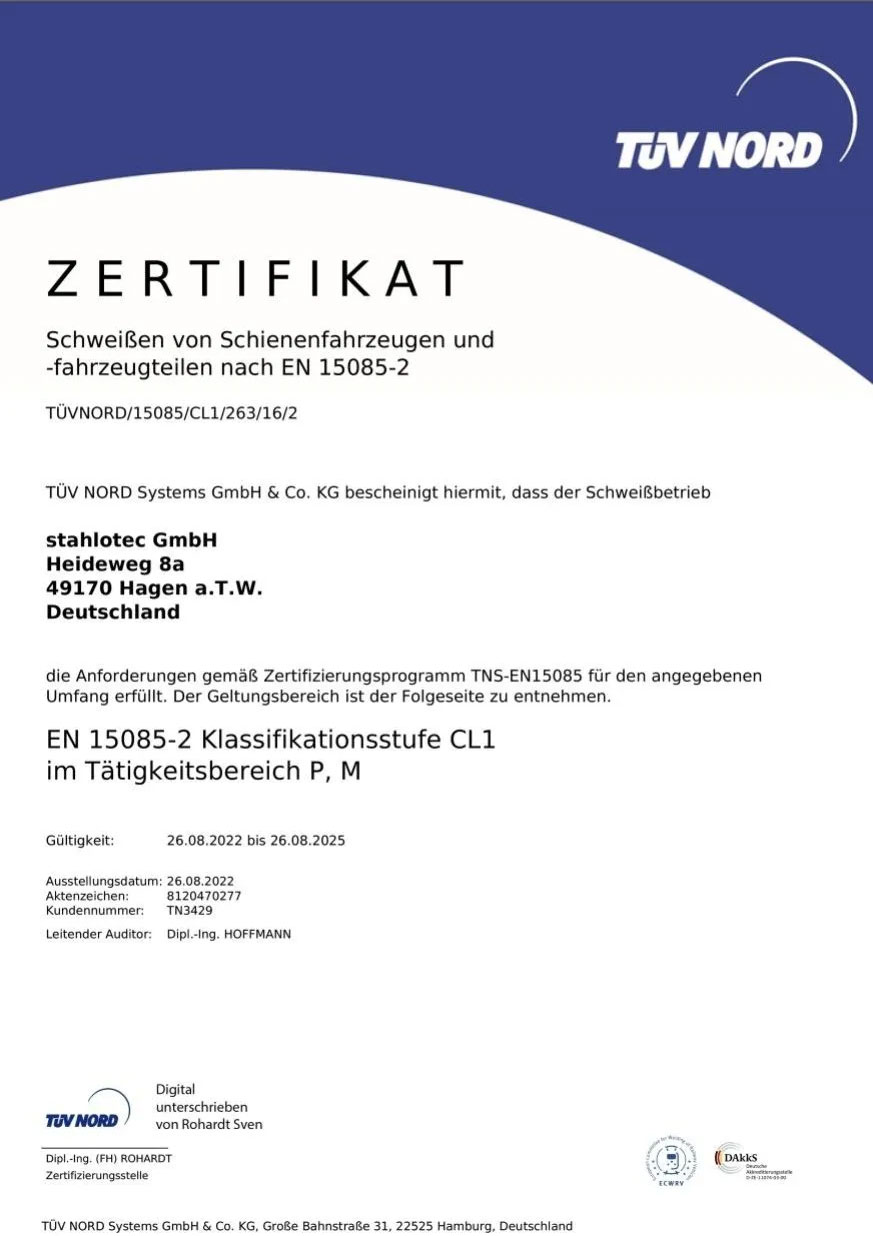

OUR QUALITY PROMISE FOR OUR CUSTOMERS

BACKGROUND

As an expert in handling contracts for welding tasks of all shapes and sizes, stahlotec GmbH is also in demand as a service provider to the coal and steel industry. Constant high loads and significant material wear are particularly common among the types of crushing tools that are used to process abrasive materials such as stones, oil sand and ores. As an expert in wear protection, stahlotec is continually investing in research and development for new production processes in this field.

PROJECT OBJECTIVES

Working with Thyssen Krupp Industrial Service, we aim to develop a process that will use lasers to weld hard metals for crushing tools in a metal powder matrix and refine this process for series production.

IMPLEMENTATION

In 2020, an investment was made in a 10 kW laser welding system with the aid of implementing and developing the new procedure, and new jobs were created for highly qualified specialist staff.

Copyright ©2025 stahlotec GmbH